Electrochemical Synthesis

In the field of synthesis, the focus is on the removal of particles and the protection of the smallest structures in wafer fabrication as well as the cleaning of devices for wafer production.

A further area of application in the Green Chemistry division is the resource-efficient and sustainable production of valuable chemical substances. Here, our scalable steel cells with diamond electrodes are used to produce biphenol or peroxo-dicarbonate, for example.

Semiconductor Industry: cleaning of Wafers and Devices

In semiconductor industry, DIACHEM® electrodes are profitably used for cleaning wafers and support infrastructure as well as for oxidation protection of metal-based microstructures. Cost reduction and increase of process stability are the main goals of mass production in the semiconductor industry. DIACHEM® electrodes are the main components of our partners' innovative technology used for particle removal in semiconductor industry.

The cleaning solutions generated with our technology significantly extend the application range of rinsing solutions and show properties that cannot be achieved in classical cleaning baths.

In oxidative cleaning baths a mixed solution of sulfuric acid and hydrogen peroxide is traditionally used for the wet etching process. In the new technology, the highly oxidative Caro acid is generated by electrolysis directly from the sulfuric acid. The Caro acid reacts to sulfuric acid, which can be returned to Caro acid. This technology minimizes the environmental impact and reduces costs by recycling the wet etching liquid. Our partner Kurita America Inc. uses this innovative technology to enter the semiconductor market.

Application Examples

Advantages of Wafer Cleaning with electrolyzed Water

Non-destructive particle, ion and metal removal

Avoidance of chemical waste and disposal

Protection of metals against oxidation in the cleaning bath

Wide ORP and pH window

Substitution solution for external chemical supply

Recyclability of Electrolyzed Sulphuric Acid (ESA)

Efficient ozone generation

This is how Wafer Cleaning works

Our Product for Cleaning Processes in Semiconductor Industry

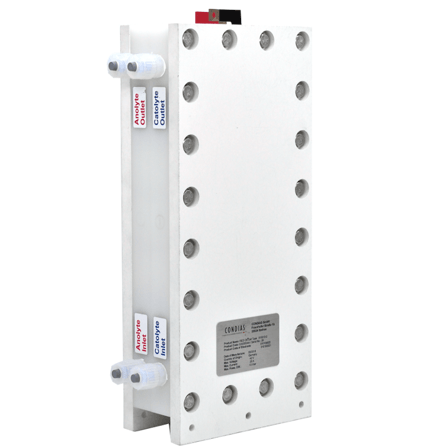

he RED OX® cell:

for cleaning processes in the semiconductor industry

“Green chemistry”: Sustainable Synthesis of valuable Materials

The environmentally friendly and sustainable production of chemical compounds is one of the cornerstones of green chemistry. In the context of EAOP® (Electrochemical Advanced Oxidation Process), a durable and highly efficient diamond electrode sets new standards in terms of cost-effectiveness and sustainable technology.

Highly oxidizing species such as PODIC® (peroxo-dicarbonate) can even be produced in high concentrations only by using diamond electrodes. In addition to the outstanding performance of the DIACHEM® electrode in aqueous media, innovative synthesis routes can also be followed in organic solvents. Biphenol synthesis is one of several applications that could be realized with high efficiency in the BMBF project EPSYLON.

The free scalability of our electrolysis cells ensures that there is no technology break between laboratory, pilot phase and production.

Applications / Projects

Advantages

Sustainable added value

Closed material cycles

Scalable systems

Sustainable and environmentally friendly production of high-quality chemicals

Use of renewable energies

Low costs

The peroxo-dicarbonate anion is characterized by its high oxidation power combined with very low activation energy. Due to its comparatively complex synthesizability it has been difficult to successfully use it as an oxidizing agent for a long time. In particular, boron-doped diamond stands out for the oxidative coupling of two carbonate irons. The efficient and stable synthesis route at BDD opens up completely new possibilities in electrosynthesis.

For example, the conversion of lignin with sodium peroxodicarbonate offers an innovative, ecological and resource-saving synthesis for the natural substance vanillin. Lignin is available on an industrial scale. As an ubiquitous biopolymer in trees and grasses it is an integral part of the cell walls and ensures the plant´s structural integrity.

CONDIAS is involved in the EU-funded project LIBERATE, which focuses on the production of vanillin from lignin.